CONSTRUCTION OF OFFICE BUILDING

A SUMMER TRAINING REPORT

Submitted by

SHRISHTI TRIPATHI

1684000047

In partial fulfilment of industrial training for the award of the degree of

BACHELOR OF TECHNOLOGY

IN

CIVIL ENGINEERING

Rajkiya Engineering College, Mainpuri

NH84 Road Nauner, Mainpuri – Shikohabad Road

Mainpuri, Uttar Pradesh 205001

JULY 2019

ABSTRACT

The internship report in broad-spectrum contains all the details of the project in which I explained my 1-month experience. This report consists of a description of the materials and construction process of an office building.

In the opening section of this report, I give introductory details of the Central Public Work Department under which I did my internship and then I give some glimpse of Vijaya Bank whose construction is running since my project is based on this i.e. construction of office building for Vijaya Bank.

The materials used in this project is cost effective and of better quality as per specifications given by engineer.

This building is built by looking at the modern era and in this everything is based on the new technology.

In the last and final section I mainly explain about the ongoing works on site and different images of site work and also conclusion which I learn from the beginning to the end of the internship.

ACKNOWLEDGEMENT

I wish to express deep sense of gratitude to my guide Manas Sir, AEE and Dinesh Sir, JE for their valuable guidance, constant support, and encouragement throughout the field internship. Their attitude of generating innovative solutions to problems and making thoughts into reality through hard work are a source of inspiration for me. Their approachable nature creates a comfortable working environment. It has been a great learning experience working under them.

It is an honour to work in a cooperative environment, where one can work with zeal and enthusiasm for which I am thankful to AEE and their staff of CENTRAL PUBLIC WORK DEPARTMENT. They have provided me all the support needed throughout the internship period and also all the related information on the site for the successful completion of this project.

I am extremely thankful to my faculty Mr. Saket Rusia, REC Mainpuri and training placement cell REC Mainpuri for valuable suggestions and encouragement and also various necessary information for the report formation.

Signature of student

Table of Contents

| S. No. | Contents | Page Number |

| 1. | Title Page | |

| 2. | Certificate by Supervisor | |

| 3. | Acknowledgement | |

| 4. | Abstract |

Chapter 1

| S.No. | Content | Page Number |

| 1. | Central Public Work Department (Overview) | |

| 2. | Introduction | |

| 3. | Details of the Project | |

| 4. | Plans of Different Floors of Project | |

| 5. | Detail Report on Construction of B+S+3 buildings |

Chapter 2

Construction Process and Material Used

| S.No. | Content | Page Number |

| 1. | Earthwork Excavation | |

| 2. | Concrete works | |

| 3. | Reinforced Cement Concrete | |

| 4. | CC Block | |

| 5. | Wood work and FRP work | |

| 6. | PVC Work | |

| 7. | Steel Work | |

| 8. | Flooring | |

| 9. | Roof Treatment | |

| 10. | Finishing | |

| 11. | Aluminum Work Structural Glazing Aluminum Composite Panel | |

| 12. | Sanitary Installations | |

| 13. | Water supply | |

| 14. | Drainage | |

| 15. | Water Proofing | |

| 16. | Granite Work | |

| 17. | Rain water harvesting and tube wells | |

| 18. | Bore well | |

| 19. | Type of Tiles | |

| 20. | Type of Vitrified Tiles | |

| 21. | ACP Cladding | |

| 22. | False Ceiling | |

| 23. | Fire Rated Doors | |

| 24. | Laser Distance Meter | |

| 25. | Conclusion |

Central Public Work Department (CPWD)

An Overview

CPWD came into existence in July 1854 when Lord Dalhousie established a central agency for execution of public works and set up Ajmer Provincial Division. Through the professional expertise in disciplines including Architecture, Engineering, Project Management coupled with comprehensive experience in building construction and maintenance CPWD has been serving the nation for the last 164 years and has executed priority of works in difficult and demanding geographical and climatic conditions. It has now grown into a comprehensive construction management department, which provides services from project concept to completion, consultancy, and maintenance management.

Introduction

The Central PWD is the agency of central government operating throughout the country for planning, construction, maintenance of all works, and buildings financed from civil works budget including renting and purchase of buildings and estates work at places where directorate of Estate is not functioning. These do not include works of Atomic Energy Dept. Central Water Commission, P&T Dept. All India Radio, Space Department and Railways.

Where there is no CPWD formation within 20km from the site of works, administrative ministry is empowered to execute original works and special repairs.

Vijaya Bank was a public sector bank with its corporate office in Bangalore, Karnataka, India. It was one of the nationalized banks in India. The bank offered a wide range of financial products and services to customers through its various delivery channels. The bank had a network of 2031 branches (as of March 2017) throughout the country and over 4000 customer touchpoints including 2001 ATMs.

On 17 September 2018, the Government of India proposed the merger of Vijaya Bank and Dena Bank with the Bank of Baroda, pending approval from the boards of the three banks. The merger was approved by the Union Cabinet and the boards of the banks on 2 January 2019. Under the terms of the merger, Dena Bank and Vijaya Bank shareholders received 110 and 402 equity shares of the Bank of Baroda, respectively, of face value ₹2 for every 1,000 shares they held. The merger is effective from 1 April 2019.

The bank has provided sanitation facilities to 56 govt. schools mostly in rural areas. The bank has established 32 rural health centers where patients are provided primary healthcare and medicine free of cost. It has also has devised a unique programme to adopt girl children. The policy of Girl Child Adoption was introduced by the bank in 2011 under which the bank adopts girl children from SC/ ST/ OBC/ economically weaker sections / backward areas/ poor families from the age of 5 years onwards to promote girl child education, mostly from rural and backward areas. The bank has adopted 1163 girl children all over the country.

DETAIL OF THE PROJECT

The name of the project is Construction Of Office Building For Vijaya Bank. The project is running at Defence Colony Indira Nagar, Bangalore, Karnataka.

The project was started in 2016 and had time limit of 12 months but unfortunately due to some reasonable delays it was delayed and now finally it is on the finishing work. The work includes internal water supply, sanitary installations, drainage and electrical installations.

This project is based on the modern construction work. All over the project work RCC is being done not the lime concrete especially in foundation work previously lime concrete was used in place of RCC work.

The name of the contractor for this project is M/s. B.K. Deshmukh Construction Company. The estimate cost for this project is Rs.3,39,16,568/ -( Civil:Rs.2,32,44,941/ – + Electrical Rs.1,06,71,627/-).

This building is designed for B+S+3 upper floors only.

Before taking any project the following steps to be taken are as follows:

- Client requisition by all government agencies/ autonomous/state agencies.

- Preliminary estimate based on PAR (Plinth Area Rate).

- Administrative approval from the clients.

- They also give simultaneous expenditures sanctions.

- Detail estimate based on DSR (Delhi Schedule Rate) and market rate.

- Obtaining technical sanction.

- NIT (Notice Inviting Tender)

DETAIL REPORT ON CONSTRUCTION OF B+S+3 BUILDING

SEQUENCE OF STRUCTURE WORK:

- Site Clearance

- Demarcation of Site

- Positioning of Central Coordinate, Surveying and Layout

- Excavation

- Laying of RCC

- Bar Binding and Placement of Foundation steel

- Shuttering and Scaffolding

- Concreting

- Electrical and Plumbing

- Deshuttering

- Brickwork

- Doors and Windows frames along with lintels

- Wiring for electrical purposes

- Plastering

- Flooring and Tiling work

- Painting

- Final completion and handling over the project

Construction Process and Material Used

- Earthwork excavation: By mechanical means (Hydraulic Excavator), Excavating trenches of required width for pipes, cables, etc including excavation for sockets, and dressing of sides, ramming of bottoms, filling available excavated earth (excluding rock).

- Concrete works: In site cement concrete of specified grade is provided in retaining walls, return walls, columns, piers, abutments, pillars, posts, struts, buttresses, parapets, coping, anchor blocks, window sills, sunken floor, etc. then damp-proof course 40mm thick with cement concrete 1:2:4 is provided and also extra concrete is provided for waterproofing material, in addition, there is an application of a coat of residual petroleum bitumen of grade VG-10.

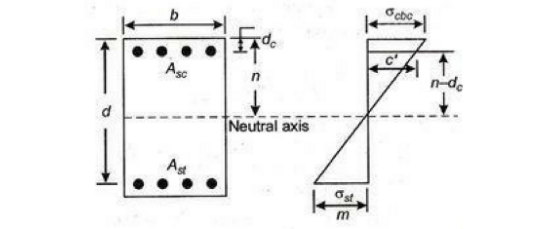

- Reinforced cement concrete: In this project, ready mix concrete is used for the RCC work. According to IS-4926 the definition of ready-mix concrete is: “Concrete delivered at the site or into the purchaser’s vehicle in a plastic condition and requiring no further treatment before being placed in a position in which it is to set and harden.”

Ready-mix concrete is a type of concrete that is manufactured in a cement factory using cement content as per approved design mix and then delivered to a worksite, by truck mounted with mixers or by transit mixers.

Note:

- Part of OPC 43 grade cement (conforming to IS8112) can be substituted with Ground Granulated Blast furnace slag (GGSB) to a minimum of 30%.

- Quantity of cementitious material considered in this item is @340 kg/cum (240 kg OPC 43 grade cement + 100kg GGBS).

- Alternatively, Portland Pozzolana Cement (Conforming to IS 1489-part 1) with minimum of 30% fly ash content can be used instead of OPC 43 grade and GGBS.

- Reinforcement for RCC work including straightening, cutting, bending, placing in position, and binding all complete using TMT bars of grade Fe 500D.

- CC Block: A concrete block is primarily used as a building material in the construction of walls. A concrete block wall can be laid in less time and may cost up to half as much as a similar brick wall. The concrete blocks are generally made using concrete which is a mixture of powdered Portland cement, water, M-Sand, and gravel. In Bengaluru, brickwork is not used since clay is not good as to manufacture good quality bricks that’s why in place of bricks, CC block is used.

- Woodwork and FRP work: Woodwork is provided in frames of doors, windows, clerestory windows, flush door shutters and fixed in position with dash fasteners and FRP work is provided in bright finished stainless steel sliding door bolts with nuts and screws, handles of grade AISI 316, CP brass magnetic door stopper, the hydraulic door of “DORMA KVA”, and providing and fixing in position 2-hour fire-rated doors.

- PVC work: In the Vijaya bank site factory-made UPVC sliding windows or equivalent multichambered and stiffened/reinforced framed windows are provided and fixed.

- Steelwork: 1mm thick M.S. sheet door with a frame of 40*40*6 mm angle iron and 3 mm M.S. gusset plates using M.S. angles for diagonal braces is provided.

- Flooring: Granite stone flooring with machine cut 18mm thick mirror polished, blue pearl, vitrified tiles, cement concrete tiles of M/s. Eurocon / M/s. Ultra of different shade, color, and pattern, ceramic glazed wall tiles of size not less than 300*400 mm is used for making the floor.

- Roof Treatment: Cement-based waterproofing treatment including preparation of surface as required for treatment of roofs, balconies, terraces, etc. is provided consisting of following operations like applying a slurry coat then laying brickbats with mortar using broken bricks after 2 days second coat of cement slurry with waterproofing compound is laid then lastly finishing the surface flooded with water for a minimum of 2 weeks for curing.

- Finishing: 12mm cement plaster of mix finishing with Premium Acrylic Smooth exterior paint of required shade using APEX PAINT/ DULUX WEATHER SHIELD is used. Then provide and apply white cement-based Putty of thickness 1mm, and finally paint walls with acrylic emulsion paint 2 coats then finishing with polyurethane paint at all locations.

- Aluminium work Structural Glazing Aluminium Composite Panel: In this project at all heights framework for semi-unitised triple barrier hybrid system of structural glazing fabricated with extruded powder coated Al sections is provided, and also at all heights structural glazing with 6 mm thick magnetron sputtered soft coated, solar control glass of blue colour toughened having visual light transmission is provided, with fixing in position flashings of solid Al sheet 1mm thick and making provision for drainage of moisture/ water that enters the curtain glazing system to make it watertight.

- Sanitary installations: For sanitary work under counter basin oval of size 195*600*425mm, bottle trap, angular stop cock, pillar cock, wall hung WC, slim concealed cistern body, control plate white, two-way bibcock, hand shower, metropole flush valve dual flow, soap dispenser-push button, single towel rail, a mirror of superior quality, urinal partition pivot door, and the terminal guard is provided.

- Water supply: CPVC pipes, having thermal stability for hot and cold water supply including all CPVC plain and brass threaded fittings, gunmetal gate valve with CI wheel, and non-return valve of approved quality is used for drinking purposes and UPVC pipes are used for wastewater. UPVC is made without adding plasticizers whereas CPVC is made by adding plasticizers and it is chlorinated as well.

- Drainage: Non-pressure NP2 class RCC pipes with collars jointed with a stiff mixture of cement mortar 1:2, square mouth SW gully trap class SP1and then constructing brick masonry manhole in cement mortar 1:4 is used for drainage work.

- Water Proofing: For waterproofing treatment in the sunken portion of W.Cs, bathroom, etc., by applying cement slurry mixed with waterproofing cement compound, 1.2 mm thick EPDM membrane is laid.

- Granite Work: 18 mm thick granite gang saw cut granite, mirror polished, machine cut for kitchen platform, vanity counters, window sills is provided and fixed. Extra granite work is used for washbasin.

- Rain Water Harvesting and Tube wells: Boring and drilling bore well of required dia for casing/ strainer pipe are provided and for supplying, filling, spreading and leveling stone boulders of size range 5 to 20 cm is used.

- Borewell: Engaging a water diviner for identifying the location of bore well to be provided. Then provide PVC pipes in bore well etc complete for all depths.

+

TOPICS EXPLAINED DURING INTERNSHIP

TYPES OF TILES

Following are the types of tiles based on surface of application:

- Roofing tiles,

- Flooring tiles,

- Wall tiles, and

- Partition tiles.

The roofing tiles are earthenware that is baked products. Its manufacture is similar to that of brick.

The wall tiles as well as the floor tiles, are employed in the interior as well as the exterior of the building. This is mainly employed based on the requirement of decoration or aesthetics. These belong to the class of ceramics and are called as white wares.

Types of Flooring Tiles

- Terrazzo Tiles,

- Chequered Tiles

- Glazed Tiles

- Vitrified Tiles

- PVC Tiles

TERRAZZO TILES

- Terrazzo tiles are available in the market with sizes varying from 20 cm x 20 cm to 30 cm x 30 cm and thickness varying between 2 cm to 3 cm. Such tiles can be used in the living room, bedrooms, etc as also in the treads and risers of the stairs.

- The tiles are laid on the bare concrete or RCC slab usually by providing a cement sand mortar of average 3 cm thickness.

CHEQUERED TILES:

- The chequered tiles are similar to the terrazzo tiles except that they have groves of about 2.5 cm in both directions. The method of laying such tiles is similar to that of laying other tiles. Care has to be taken to finish the grooves in a proper manner. Chequered tiles can also be provided on the walls to give a different look. Usually, they are costlier than the plain terrazzo tiles.

GLAZED TILES

- Glazed tiles are available in the market having either a glossy finish or a mat finish. Tiles having a mat finish are usually provided in wet locations in the house like kitchen, bath, WC, or in exterior locations like balconies, etc to reduce the chances of slipping.

- They are usually available in sizes of 10 cm x 10 cm, 15 cm x 15 cm, or 10 cm x 20 cm in white or different colors. Tiles having patterns are also available in the market.

VITRIFIED TILES

- Vitrified Tiles are composed of quartz, silica, clay, and feldspar. These materials are combined together with the process of vitrification. The tiles are manufactured by the Hydraulic press method.

- Vitrified tiles are increasingly being adopted for the construction of floors in residential buildings. They give a good look and can be cleaned easily, they are quite costly as compared to the other type of tile flooring.

- Vitrified tiles are available in glossy or mat finish having different designs and patterns. Sizes upto60 cm x 60 cm are also available and accordingly, each tile covers a large area.

PVC Tiles

- PVC tiles are being used for flooring in residential as well as non-residential buildings. They can be provided for decorating the floors.

- These tiles are costly and acoustically they have a superior performance although they are combustible. They are however easy to clean and maintain.

- PVC tiles are usually square in shape having sides of 30 cm, 60 cm or 90 cm.

Types of Vitrified Tiles

Vitrified tiles could be segregated into various types depending upon the manufacturing process. They can be classified into –

- Double Charged Vitrified Tiles:

In this process, two kinds of colour are fed into the machine resulting in a very thick layer of a double coloured design on the tile. This layer of colour and design is around 3-4mm thick. These tiles are good for high traffic areas.

- Full Body Vitrified Tiles:

In Full body vitrified tiles while designing the colour is not only on the top but seeps through the whole tile. In this method the scratches on the tiles become invisible because the tile is homogeneous and coloured throughout. Full body vitrified tiles are suggested for heavy traffic areas.

- Soluble Salt Vitrified Tiles:

In Soluble Vitrified tiles liquid colour screen printing is done on the tile before the tile is fired. Soluble salts are used to penetrate into the vitrified tile and give colour, designs and create patterns on the tile.

- Glazed Body Vitrified Tile:

Glazed body vitrified tiles are tiles that are finished with a layer of liquid glass. The glazed body adds extra shine to the tile and protects the tile from any kind of stains.

ACP CLADDING

A Cladding gives style not only protects your building from the elements of nature but also gives it a great appearance. It can also be installed easily over materials like brick, concrete. ACP is mainly used for external and internal architectural cladding, facades of buildings, false ceilings, and display panels.

ADVANTAGES

- Adding true beauty to a structure.

- Easily & quickly processed long-lasting durable.

- Excellent weather resistance.

- An economical option.

- Outstanding thermal comfort.

FALSE CEILING

- A dropped ceiling or false ceiling is a secondary ceiling, hung below the main (structural) ceiling, and is a staple of modern construction and architecture in both residential and commercial applications. Modern dropped ceilings were initially created to hide the building infrastructure, including piping, wiring, and/or ductwork, by creating a plenum space above the dropped ceiling, while allowing access for repairs and inspections.

- Drop ceilings may also be used to hide problems, such as structural damage. Dropped ceilings were made of basic white tiles, and in different sizes, colors, materials, visual effects and shapes, patterns, and textures as well as support systems.

- A typical dropped ceiling consists of a grid-work of metal channels in the shape of an upside-down “T”, suspended on wires from the overhead structure. These channels snap together in a regularly spaced pattern of cells.

- Each cell is then filled with lightweight ceiling tiles or “panels” which simply drop into the grid. The cell size in the suspension grids is 600×600 mm, while the ceiling tiles are slightly smaller at 595mm x 595mm or 595mm x 1195mm.

FIRE RATED DOORS

A fire-rated door or fire-resistant door is specially constructed to slow or prevent the spread of fire and smoke. A fire-rated door is a very heavy door made of materials like metal or gypsum. “The term ‘fire-rated’ means that the door, when installed properly, is not supposed to combust during a certain time frame in the average fire.” While time ratings vary, standard ratings include 20- to 90-minute doors and the door which is used in this site is 2 hours.

Fire-rated doors are more common in commercial buildings than in residential structures. Fire-rated doors are often installed in public buildings and in office buildings. These doors are made of combustible materials and will eventually burn through in a fire. However, they will resist the penetration of heat and flames to slow the fire for a specified time period.

LASER DISTANCE METER

Now a days for measuring distance laser distance meter is used. It works by measuring the time, it takes a pulse of laser light to be reflected off a target and returned to the sender. This is known as the “time of flight” principle, and the method is known either as “time of flight” or “pulse” measurement. This type of measurement is fast and effective.

![]() CONCLUSION

CONCLUSION

It was a wonderful and learning experience for me while working on this project. This project took me through the various phases of project development and gave me the real insight into the world of civil engineering (building construction).

The main aim of studies within this project was to investigate how a structure is constructed within its desired properties. We got to know about the basic and advanced techniques of building construction.

I cleared many doubts regarding building construction. Overall it must be said that the construction methods and quality control on a project needs a very good coordination and large quantities of man power, equipment and funds.

We can conclude that there is a difference between the theoretical and practical work done. As the scope of understanding will be much more when practical work is done. As we get more knowledge in such a situation where we have a great experience doing the practical work.

Right Understanding

Right Understanding We all know that the Human Desire is to be in continuous happiness which is the need of I (self). But do you know, from where Continuous happiness will come? No, right! So continuous happiness is to be in Right Understanding, Right Feeling, and Right Thought that is Activity of I (Self). Do…

Where We Are

Where We Are (Self-Evolution) We exist as human being. We want to live a fulfilling life. We have some desires and we have some programs for the fulfilment of it. We need to understand our basic aspiration and program for its fulfillment correctly and comprehensively. Only then, we can ensure fulfillment. We should explore ourselves…

Highway Construction

Highway Construction Embankment Construction Materials and General Requirements The materials used in embankments, subgrades, earthen, shoulders, and miscellaneous backfills shall be soil, moorum, gravel, a mixture of these. Clay having liquid limit exceeding 70 and plasticity index exceeding 45; shall be considered unsuitable for embankment. Sub-grade and top 500mm portion of the embankment just below…

Special Concretes

Special Concretes Concrete is most vital material in modern construction. In addition to normal concrete, other varieties in use are, high strength and high-performance concrete, self-compacting, lightweight, high density, fiber reinforced, polymer, colored concrete, etc. The making of concrete is an art as well as a science. Special types of concrete are those with out-of-the-ordinary…

Marketing Practices

Marketing Practices Success in the world of business, no matter how you earn it, you have to rule on the marketplace. Although luck plays a role in the outcome of the market strategies. In the business decisions, there should be the understanding of market otherwise the failure will take place by the marked decisions. While…

Risk Analysis

Risk Analysis The risk that remains after the implementation of controls is called the residual risk. All systems will have residual risk because it is virtually impossible to completely eliminate risk to an IT system. In other words, we can say that there are two main parts of the security risk analysis known as Quantitative…