What do you know about Co-Incineration?

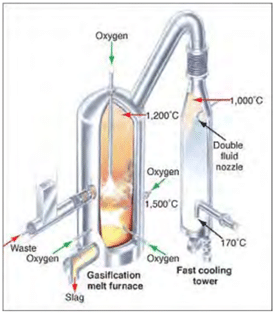

Co-incineration of solid wastes is, also, a mass combustion process, which occurs, mostly, in cement furnaces, simultaneously with the clinker production. The difference results that this is a “dry” process, because there isn’t, in any part of the process, the flowing of water/steam water as an industrial utility (Puna, 2002). On another hand, the co-products (dangerous ashes, slag’s and several heavy metals) are all incorporated in the hardness cement crystalline structure, becoming inerts. Regard the figure 5, which shows a typical scheme of a co-incineration furnace of dangerous solid wastes.

The co-incineration is a thermal destruction technique applied to several industrial solid wastes and, these wastes are valorized as raw-materials and/or fuels. Several industrial processes that work at high temperatures can be used for waste elimination, taking advantage of their calorific power. The elimination of industrial wastes with a calorific power minimum of 5000 kJ/kg in an industrial process can be considered as a technique with energetic valorization (Oliveira, 2005).

This method of thermal destruction of solid wastes has several benefits, even as an environmental perspective, but also, and more important, as an energetic perspective, because it enables to substitute of fossil fuels, like fuel oil, natural gas, etc., by dangerous wastes. These wastes are valorized in two forms: can be used as raw materials and, as a fuel supplier to burning furnaces (Puna, 2002). However, the substitution of fossil fuels by dangerous wastes cannot increase the atmospheric pollutant emissions, resulting from combustion processes, in comparison with the normal use of conventional fuels.

The co-incineration can be conducted in different industrial processes, like, for instance, in cement furnaces, or in industrial boilers. Nevertheless, the

co-incineration in cement furnaces is considered the most efficient process of

co-incineration, especially to dangerous solid wastes (Formosinho et. al., 2000).

The combustion of wastes in cement furnaces occurs at the same time with the production of clínquer (cement product intermediate). The main characteristics in the co-incineration process of solid wastes in cement furnaces are the following ones (Scoreco, 1997):

• Thermal valorisation method, alternative to dedicated incineration, only applied to burning wastes with higher calorific power, like, used oils and fatty slushes of industrial wastewaters treatment units;

• It’s necessary a previous treatment for wastes before entering in the cement furnace, through physical and chemical process (impregnation, melting, centrifugation, fluidization);

• The industrial solid wastes are burned as fuel, with oxygen from air, in a mass combustion process, with temperatures between 1400ºC-1500ºC;

• The combustion gases achieve maximum temperatures near from 2000ºC in the main burner and stay at temperatures higher than 1200ºC in the second burner, with time residences between 4-8 seconds;

• The wastes admitted to co-incineration in cement furnaces cannot be contain chlorine contents higher than 1% (w/w), due to the significant production of dioxins/furan’s, when the combustion gases are cooled faster at the outlet of clínquer furnace;

• These operating conditions are crucial to reduce and avoid the production of those macromolecules with higher molecular weight. It’s important to remind that, dioxins/furan’s molecules are produced, in a combustion process, with temperatures between 250-900ºC and, with significant contents of Chlorine in the solid wastes.

Besides that, the chlorine is harmful to the consolidation of cement structure, raising several weaknesses;

• It’s necessary also, like in the dedicated incineration, the treatment of combustion gases, before they go out to the atmosphere, with temperatures between 150-200ºC. To achieve this purpose, the process of cooling the combustion gases has to be very fast and, in a temperature gradient between (1000-1200) ºC until (150-200) ºC;

• The temperatures profile and the time residences are higher than any other combustion process, like dedicated incineration;

• Basically, a cement furnace is a place with optimal conditions to burn and eliminate any organic waste with capacity to be submitted for incineration;

• It’s extremely important the control of operating parameters, like, temperature, oxygen content and time residence of combustion gases, to ensure an efficient and safety burning of solid wastes, mainly, the dangerous ones;

• The thermal energy to feed the furnace is obtain by a variety of auxiliary fuels, but with large preference to coal and/or pet-cock, with very low contents of sulphur, to avoid the production of SO2;

• The burning dangerous industrial wastes with high calorific power can replace the coal, as fuel to supply the co-incineration furnace, until 40%, with, mainly, used oils, solvents and organic slushes.

It is also important refer that, the combustion gases, before they go out to the atmosphere, are previously treated by physical and chemical appropriated process, like in dedicated incineration, in order to maintain the air quality and, therefore, assure that the gaseous emissions could be above their legal emission limit values, defined in the European and Portuguese legislation. Heavy metals, Dioxins, Furans and PCB’s are treated by adsorption with activated carbon, while the acid gases (HCl, HF and SO2) are treated by chemical reaction with lime milk (Ca(OH)2) (Russo, 2005).

The NOx gases are treated by injection, without catalyst, of ammonia aqueous solution, producing N2, while the almost particles are filtered with sleeves filters of higher efficiency or, with electro filters. The wastes generated by these processes are called flying ashes and they are covered in safety and appropriate landfills, after an inertization process.

This group of combustion gases treatment is performed at clínquer furnace exit and, they are the same methods, with the same technologies used in dedicated incineration.

It’s interesting to perform a comparison between dedicated incineration and co-incineration thermal methods for solid wastes.

Right Understanding

Right Understanding We all know that the Human Desire is to be in continuous…

Where We Are

Where We Are (Self-Evolution) We exist as human being. We want to live a…

Highway Construction

Highway Construction Embankment Construction Materials and General Requirements The materials used in embankments, subgrades,…